We are a state-of-the-art, sustainable electroplating company

Willy Remscheid Galvanische Anstalt GmbH is your experienced partner for precise surface finishing, innovative electroplating technology and sustainable metal finishing. We stand for German engineering, certified quality and individual solutions for demanding industries. We deliver tailor-made results for industry, trade and international clients in the field of functional or decorative coatings.

A company with tradition – surface finishing since 1911

We come from the traditional blade-making town of Solingen and stand for innovative German engineering, certified quality and customised solutions for demanding industries. Willy Remscheid Galvanische Anstalt GmbH was founded in 1911 and has stood for the highest quality in electroplating technology for over 100 years.

As an owner-managed family business in its fourth generation, we combine experience with state-of-the-art technologies.

We offer everything from a single source: from consulting and development to material procurement, electroplating, assembly, packaging and logistics.

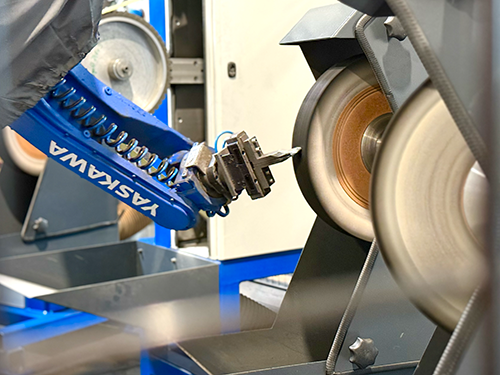

Quality and efficiency through automation

A highly automated grinding and polishing centre, two of Germany’s most modern electroplating facilities, including chromium (III), and comprehensive quality management ensure that every component is manufactured precisely according to customer specifications. Our processes include copper, bright nickel, matte nickel, semi-bright nickel, MPS nickel, crack nickel and environmentally friendly chromium (III).

We guarantee maximum process reliability and reproducibility, even for large series. We always keep an eye on the perfect interplay of design, function and corrosion protection.

Thanks to our in-house jig manufacturing and parts assembly, we can implement complex assemblies and special solutions according to individual customer requirements. Our in-house production minimises interfaces, shortens throughput times and ensures maximum quality and efficiency.

Responsibility for sustainability

Sustainability is firmly anchored in our corporate philosophy. We focus on resource-saving production, modern water recycling systems and our own combined heat and power plant, which is supplemented by a large-scale photovoltaic system.

Our processes are certified according to DIN EN ISO 9001:2015 (quality management) and DIN EN ISO 14001:2015 (environmental management). These standards and our high degree of automation enable us to guarantee consistent product quality.

Our certifications

We have been certified according to DIN EN ISO 9001:2015 since 1997 and additionally according to DIN EN ISO 14001:2015 since 2017. This means we not only guarantee the highest quality, but also sustainable and responsible business practices.